About

Powering MENA

Powering MENA with on-demand Manufacturing

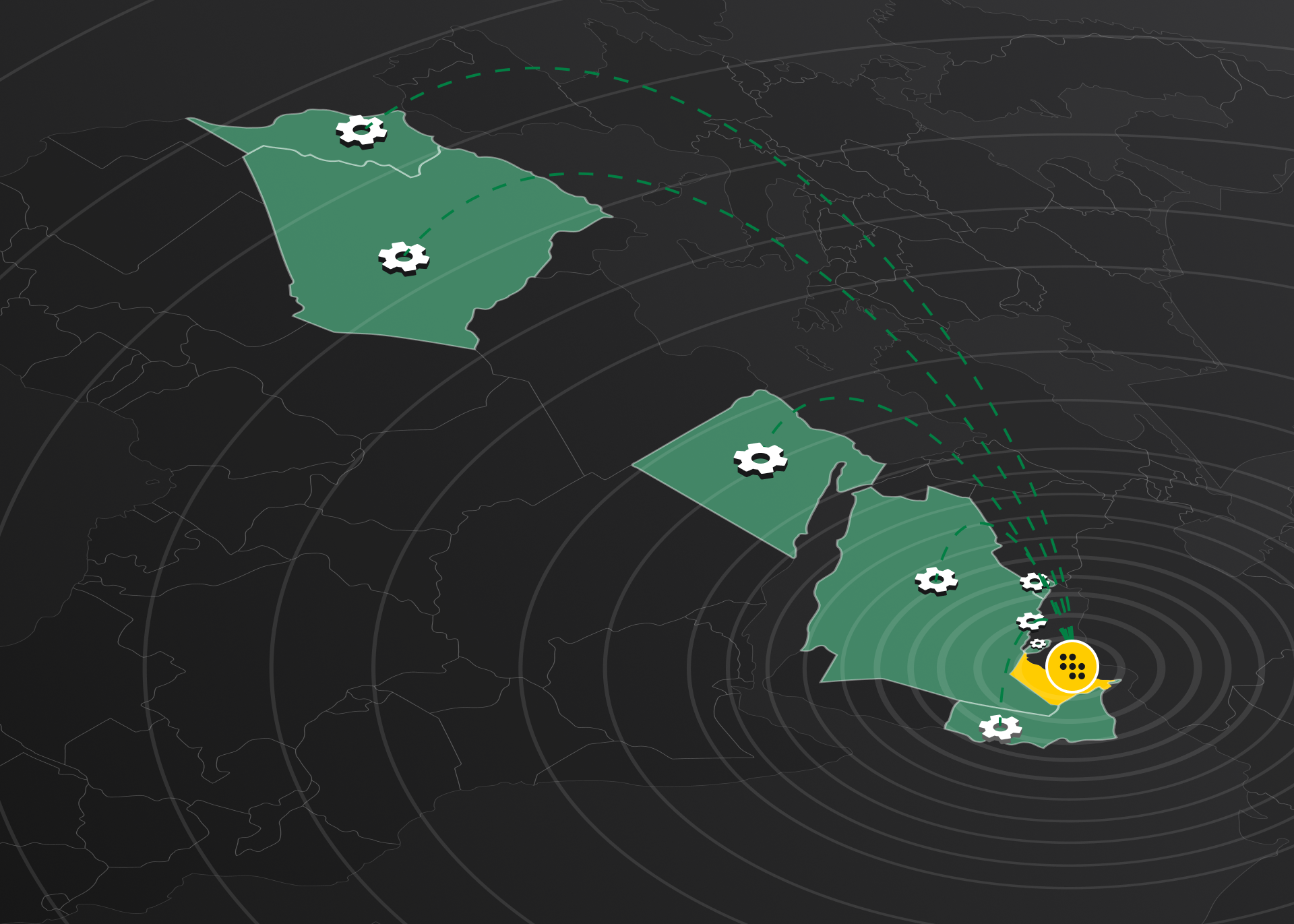

Faster Parts by Sourcing in MENA

We’ve expanded our network with local machine shops through out MENA to offer you a reliable solution for faster part sourcing. With the AM Lab, you can choose to order parts from manufacturers within your custom-clearance borders and have parts sent directly to you from our local network. This means lead times as fast as five days and fewer shipping and compliance hurdles.

Get parts machined in 5 days.

As we continue to grow our network through out MENA we’re able to offer even faster lead times. Our rapid CNC offering now includes five-day lead times for custom machined parts. All five-day CNC orders are sourced through machine shops locally and regionally.

Quality Network

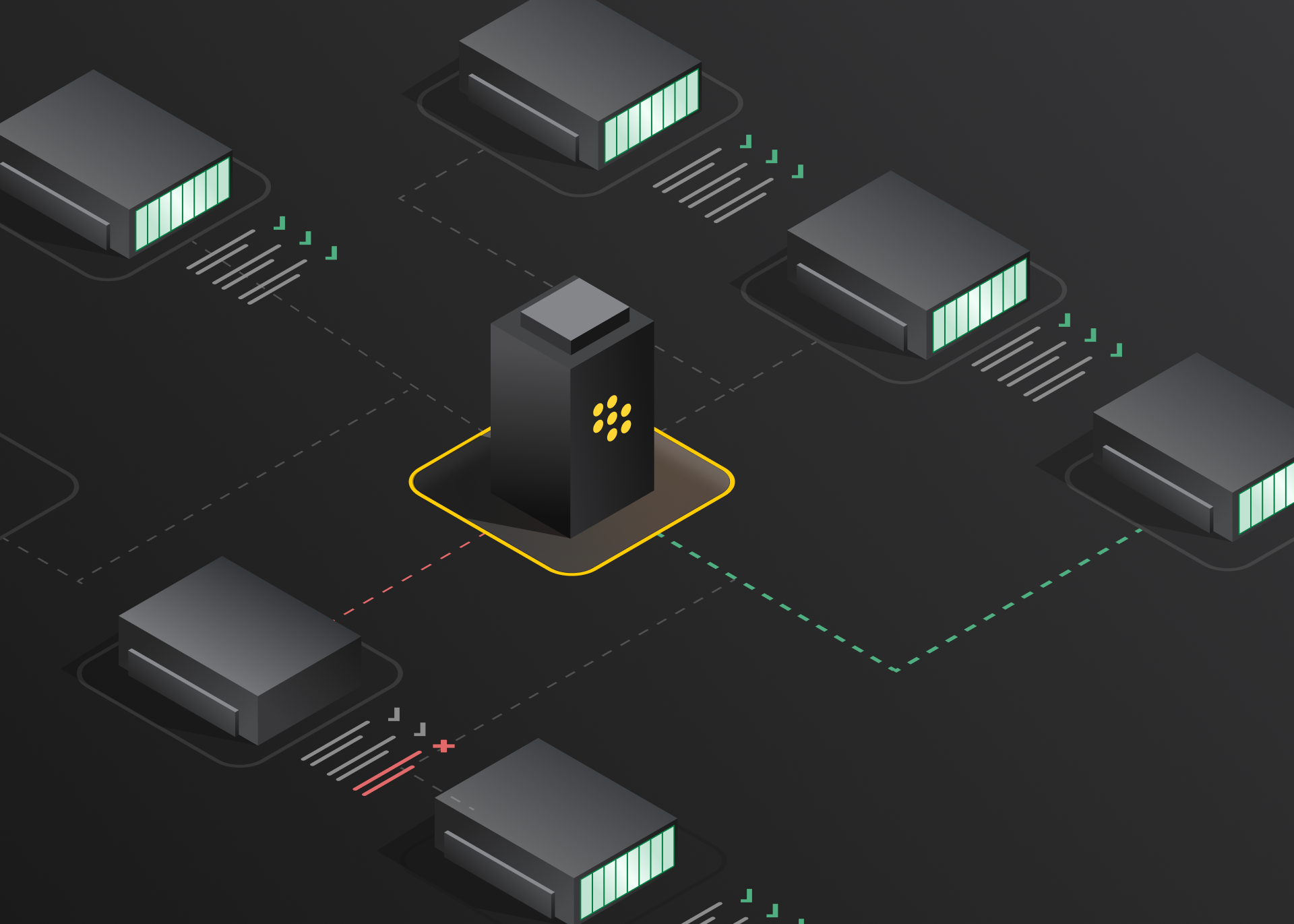

This is what our order flow looks like.

Maintaining the quality of an entire network

We work with a highly vetted network of around 300 manufacturing partners (MPs) and hold each of them to the highest quality standards. To ensure all MPs uphold the Hubs Standard, we’ve developed comprehensive systems for selecting and supporting our suppliers. We continually audit our protocols to guarantee we deliver quality parts, every time.

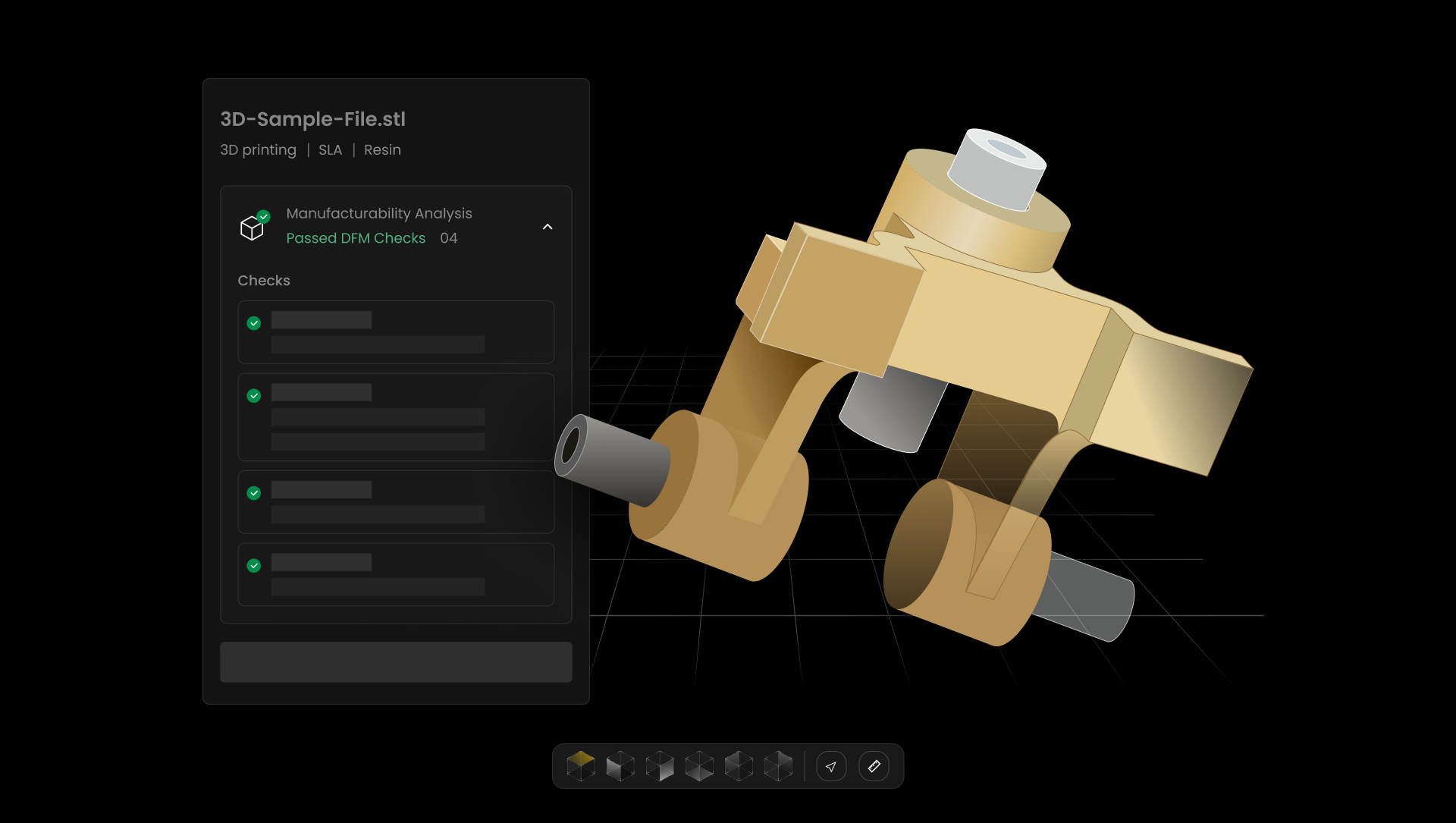

Design for Manufacturability (DFM):

Real time feedback and next best action suggested through model analysis to ensure components’ manufacturability, leading to cost savings and shorter time to production.

Manufacturing Audit

We set the bar high.

We set the bar high

AM Lab has developed a set of processes to make sure highest manufacturing standards are applied to every custom part you order. We inspect each order dimensionaly and visually, both during and after production, so that your custom components are veliered on time and to your exact specifications.

We Audit Our Network

Manufacturing partners must consistently prove their quality after joining the network. We conduct audits every two years to ensure consistent quality across our network. These audits include quality audits to test capabilities and quality control, and social audits, to confirm environmental and social compliance. We also do frequent spot checks at our major sites.

Quality Management & Quality System

- Certifications (ISO/AS)

- Quality organization

- Quality policy & objectives

Traceability

- Raw material (in & out record dates & Qties)

- Manufacturing process records

- Requirement level for suppliers/subcontractors

Reception/Incoming Quality Controls

- Identification of incoming materials

- Quality control on incoming materials and records

- Incoming and outgoing management (FIFO)

Production & Packaging

- Identification of batches of ongoing orders

- Machines & manufacturing equipment

- Quality controls during production

We Audit Our Network

Manufacturing partners must consistently prove their quality after joining the network. We conduct audits every two years to ensure consistent quality across our network. These audits include quality audits to test capabilities and quality control, and social audits, to confirm environmental and social compliance. We also do frequent spot checks at our major sites.

Become a Manufacturer

This is what our order flow looks like.

Join our partner network

We work with a global network of manufacturing partners (MPs) to deliver custom parts to customers all over the world, and we are always looking to bring on new partners to expand our capabilities and capacity.

Why become a manufacturing partner?

Hubs gives you the opportunity to take on new, high value (>€10,000) orders every week. As a manufacturing partner, you only have to focus on producing custom parts. We handle the negotiations and hassle.

Becoming a manufacturing partner is totally free. The platform is easy to use and very flexible, adapting to your workflow and capacity. You’ll have a dedicated contact at Hubs to help you get set up, answer any questions and develop your business.

We provide all partners with access to Protolabs ' competitive discounts on materials and tooling, and we handle all customer communication and payment processing.

Requirements to become a manufacturing partner

Can’t upload your files at the moment?

Use our sample part to try out our instant quoting and DfM tools.