About

We Do Not Compromise

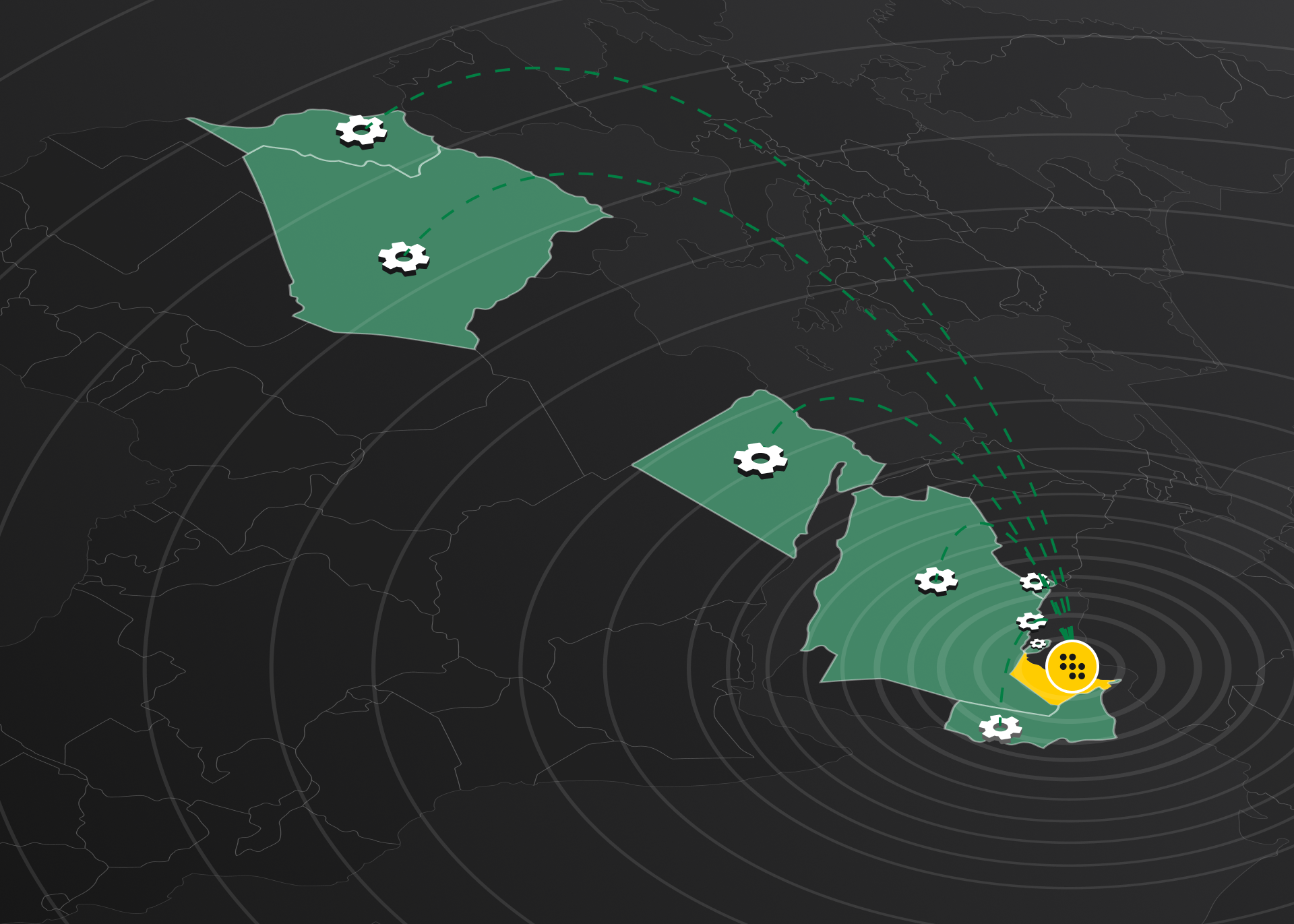

Powering MENA with on-demand Manufacturing

Introducing AM Lab's Standard

We’ve expanded our network with local machine shops through out MENA to offer you a reliable solution for faster part sourcing. With the AM Lab, you can choose to order parts from manufacturers within your custom-clearance borders and have parts sent directly to you from our local network. This means lead times as fast as five days and fewer shipping and compliance hurdles.

The AM Lab Standards

Quality Management & Quality System

- Certifications (ISO/AS)

- Quality organization

- Quality policy & objectives

Traceability

- Raw material (in & out record dates & Qties)

- Manufacturing process records

- Requirement level for suppliers/subcontractors

Reception/Incoming Quality Controls

- Identification of incoming materials

- Quality control on incoming materials and records

- Incoming and outgoing management (FIFO)

Every Custom parts meets the AM lab

We’ve expanded our network with local machine shops through out MENA to offer you a reliable solution for faster part sourcing. With the AM Lab, you can choose to order parts from manufacturers within your custom-clearance borders and have parts sent directly to you from our local network. This means lead times as fast as five days and fewer shipping and compliance hurdles.

Cross Docking

This is what our order flow looks like.

Our cross docks are equipment to inspect any part

We work with a highly vetted network of around 300 manufacturing partners (MPs) and hold each of them to the highest quality standards. To ensure all MPs uphold the Hubs Standard, we’ve developed comprehensive systems for selecting and supporting our suppliers. We continually audit our protocols to guarantee we deliver quality parts, every time.

Equipment we use

Manufacturing partners must consistently prove their quality after joining the network. We conduct audits every two years to ensure consistent quality across our network. These audits include quality audits to test capabilities and quality control, and social audits, to confirm environmental and social compliance. We also do frequent spot checks at our major sites.

- Calipers and micrometers

- Gaugh blocks

- Huge gaugh

- Feeler gaugh

- Surface roughness metter

- Pin gaughes

- Protractors

- Gloss unit meter

- RAL/Pantone color charts

- Granite block inspection table

- Thread, ring and plug Go/No-Go gaughes

Documentation

This is what our order flow looks like.

Quality documentation

We track performance of our suppliers to ensure that orders meet the AM Lab Standard. We can provide certifications and reports upon request.

Certificate of Conformance

Availability: CNC machining, Sheet metal fabrication, Injection molding

Material Test Report

Availability: CNC machining (Metals)

CMM Inspection Report

Availability: CNC machining

REACH

Availability: CNC machining, Sheet metal fabrication

Metal Certificate

Availability: CNC machining, Sheet metal fabrication

First Article Inspection (FAI)

Availability: CNC machining

Dimensional Inspection Report

Availability: CNC machining, Sheet metal fabrication, 3D printing

RoHS

Availability: CNC machining, Sheet metal fabrication, Injection molding

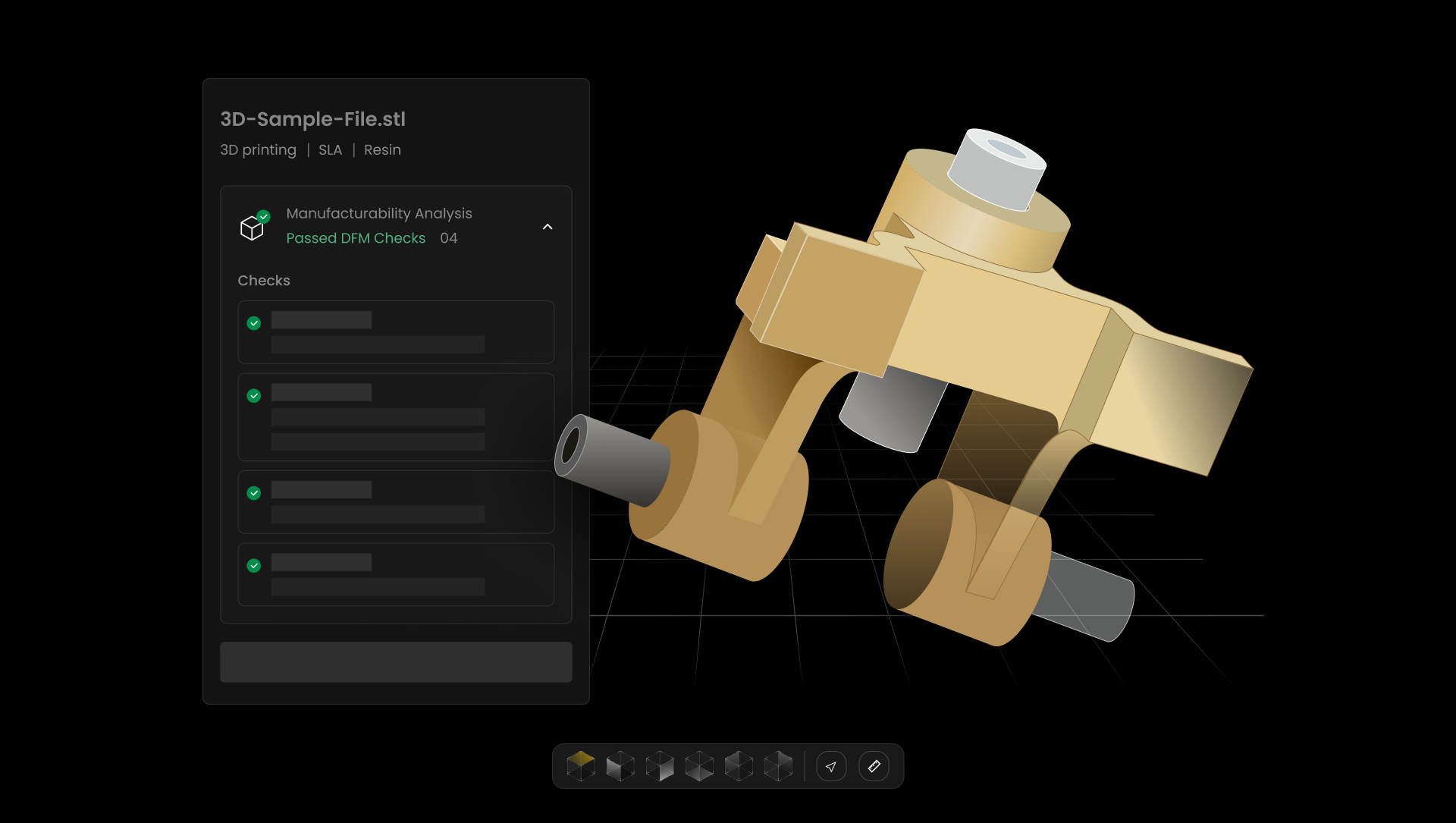

Can’t upload your files at the moment?

Use our sample part to try out our instant quoting and DfM tools.